Pigeon Point Systems

World-Class Management Components. Focused. Dependable. Proven.

Pigeon Point Systems' product portfolio includes world-class management components for modular platforms based on the AdvancedTCA (ATCA), AdvancedMC, and MicroTCA architectures, PCI management components and software, and consulting and design services. Pigeon Point Systems focuses on products and services supporting the adoption of open modular platforms. In addition, Pigeon Point Systems provides world-class components licensed by leading CompactPCI vendors and included in Windows XP Embedded.

Pigeon Point Systems' product portfolio includes world-class management components for modular platforms based on the AdvancedTCA (ATCA), AdvancedMC, and MicroTCA architectures, PCI management components and software, and consulting and design services. Pigeon Point Systems focuses on products and services supporting the adoption of open modular platforms. In addition, Pigeon Point Systems provides world-class components licensed by leading CompactPCI vendors and included in Windows XP Embedded.

Fusion-Based TCA

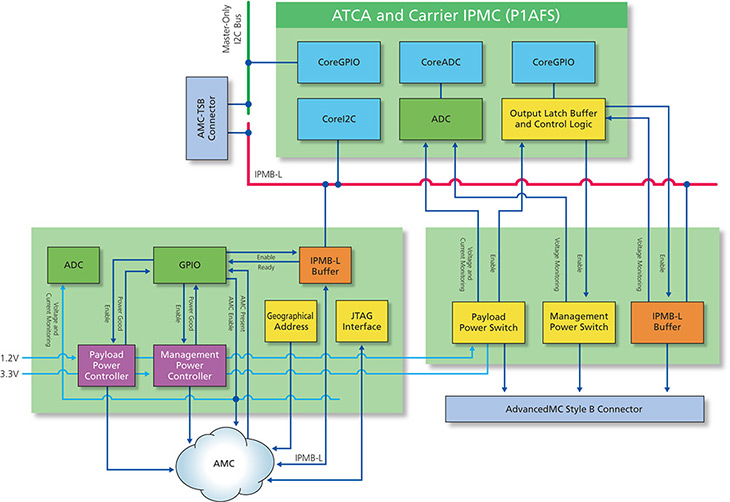

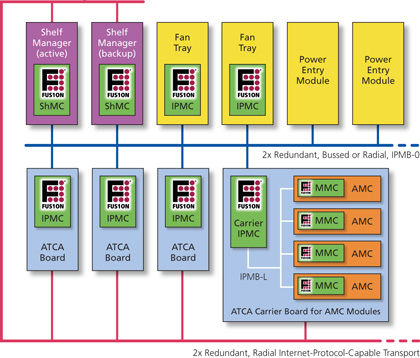

Actel and Pigeon Point Systems are working together to develop and market Actel Fusion-based solutions to speed the design of ATCA blade and AdvancedMC carrier board management controllers, with production ATCA development kits shipping in September. As future development

projects mature and are announced, the combined portfolios of Actel and Pigeon Point Systems bring development kits, reference designs, easy-to-use development environments, and expert design services to customers. Designers can address system and power management issues at the component, board, and firmware levels.

This diagram illustrates where Fusion can be used in TCA systems.

Fusion-Based Pigeon Point ATCA Development Kits

These kits enable designers to develop ATCA blade or AdvancedMC carrier products using fully ATCA-compliant Pigeon Point firmware. Customers can fully test these designs in hardware on the bench using the common ATCA development kit board. Supporting all four Serial over LAN (SOL) modes, the PPS ATCA Development Kit delivers more functionality than any other design available today, at a lower total system cost. The Fusion-based PPS ATCA solution provides direct bottom line savings in comparison with existing solutions, yielding a 37% improvement in BOM total parts count, a 27% savings in BOM cost and total cost including assembly, and a 38% reduction in board area (4,094 mm2 vs. 2,540 mm2), for a total savings of $35 per board.

Pigeon Point Systems' product portfolio includes world-class management components for modular platforms based on the AdvancedTCA (ATCA), AdvancedMC, and MicroTCA architectures, PCI management components and software, and consulting and design services. Pigeon Point Systems focuses on products and services supporting the adoption of open modular platforms. In addition, Pigeon Point Systems provides world-class components licensed by leading CompactPCI vendors and included in Windows XP Embedded.

Pigeon Point Systems' product portfolio includes world-class management components for modular platforms based on the AdvancedTCA (ATCA), AdvancedMC, and MicroTCA architectures, PCI management components and software, and consulting and design services. Pigeon Point Systems focuses on products and services supporting the adoption of open modular platforms. In addition, Pigeon Point Systems provides world-class components licensed by leading CompactPCI vendors and included in Windows XP Embedded.

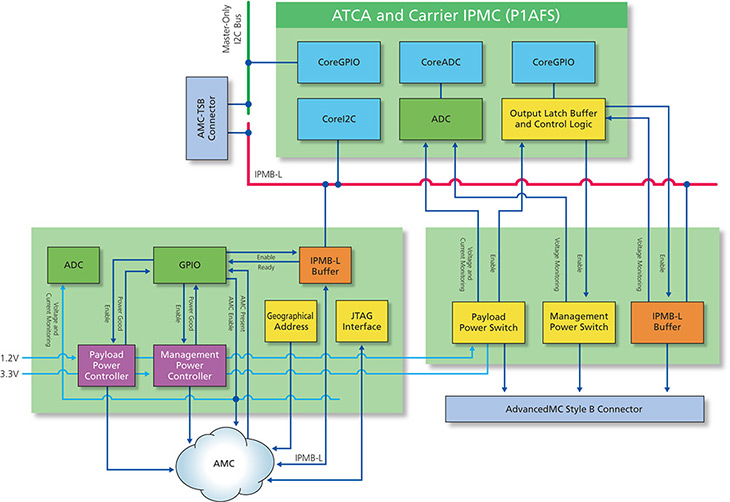

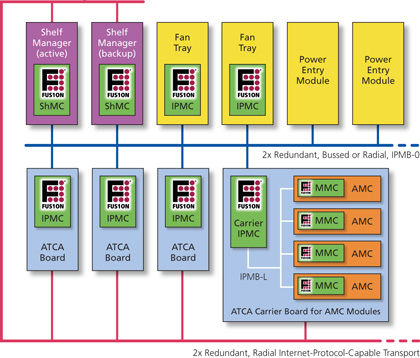

Actel and Pigeon Point Systems are working together to develop and market Actel Fusion-based solutions to speed the design of ATCA blade and AdvancedMC carrier board management controllers, with production ATCA development kits shipping in September. As future development

Actel and Pigeon Point Systems are working together to develop and market Actel Fusion-based solutions to speed the design of ATCA blade and AdvancedMC carrier board management controllers, with production ATCA development kits shipping in September. As future development

projects mature and are announced, the combined portfolios of Actel and Pigeon Point Systems bring development kits, reference designs, easy-to-use development environments, and expert design services to customers. Designers can address system and power management issues at the component, board, and firmware levels.

projects mature and are announced, the combined portfolios of Actel and Pigeon Point Systems bring development kits, reference designs, easy-to-use development environments, and expert design services to customers. Designers can address system and power management issues at the component, board, and firmware levels.